Balancing Efficiency, Hygiene, and Operating Costs

In the competitive foodservice industry, kitchen efficiency is no longer optional—it’s essential. For high-turnover restaurants, how quickly and safely you clean dishes isn’t just a back-of-house detail—it directly impacts table turnover, staff workflow, customer satisfaction, and even profitability.

This article outlines how our commercial dishwashing solutions are designed to help modern restaurants clean more, clean better, and save more—every single day.

01|The Real Cost of Manual Dishwashing

Many restaurants still rely on manual dishwashing. At first glance, it may seem cost-effective, but in reality, it leads to:

High labor costs: Dishwashing staff have high turnover rates and require constant retraining.

Unstable hygiene standards: Inconsistent temperatures and hand washing lead to residue and sanitation issues.

Bottlenecks during peak hours: Dishes pile up, slowing down service and table turnover.

Unmonitored water and energy usage: Hand washing often leads to excessive waste of hot water and electricity.

The solution is simple: integrated, standardized dishwashing systems built for commercial use.

02|Our Solution: Tailored to Restaurant Size and Workflow

✅ For Small to Medium-Sized Restaurants

Double-Rack Hood-Type Commercial Dishwasher

Key Features:

Dual-rack design doubles capacity per wash cycle—ideal for peak lunch and dinner rushes.

High-temperature wash cycles (75°C wash, ≥82°C final rinse) eliminate bacteria without added chemicals.

Energy-saving heat recovery system reduces overall energy use by 30–40%.

All-stainless-steel 304 housing, built for long-term durability.

One-touch operation with a visual control panel—minimal training required.

Best For:

Casual dining restaurants, bakeries, small buffets, or any kitchen serving 50–300 meals per day.

✅ For Large-Scale Operations

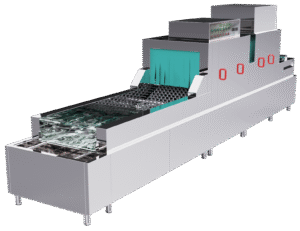

Rack Conveyor Dishwasher System

Key Features:

Continuous loading system using standard dish racks—dishes move through wash, rinse, and optional drying zones automatically.

High throughput: Handles 1,200–1,500 meal sets per hour under full load.

Modular design adapts to your kitchen layout and workflow.

Multi-stage filtration system ensures clean water recycling and prevents spray arm blockage.

Optional high-temp drying zone allows for “wash-and-use” turnover with no drying delay.

Best For:

Buffets, school cafeterias, hospital kitchens, central kitchens, or institutional dining facilities with high-volume service.

03|It’s Not Just About Clean Dishes—It’s About Long-Term ROI

Our clients choose our equipment not just for hygiene—but for meaningful cost savings and operational stability. In real-world kitchens, the results speak for themselves:

Labor savings: Replace a 3-person wash team with just 1 trained operator.

Speed & efficiency: 2x faster turnaround compared to manual washing.

Chemical-free cleaning: High-temp rinse means no residue, no smell, no extra chemicals.

Transparent water & energy use: Smart systems make cost tracking easy and reliable.

04|Final Thoughts: Standardization is the Foundation of Scalability

Your kitchen is the heart of your restaurant—and the dishwashing system is its final safeguard for food safety and service speed. Without a reliable solution, your operation is always one staff call-out or hygiene slip away from chaos.

We offer professional dishwashing equipment tailored to your restaurant’s size and flow, with:

Nationwide support

Modular customization

Remote training

Sample unit trials upon request

📩 Contact our team today to receive a personalized recommendation or to book a live demo.

Let’s build a smarter kitchen, together.